Material Tendencies: Eugeni Quitllet

Describing himself as a ‘Disoñador’, a combination of the Spanish words designer and dreamer, Eugeni Quitllet likes to enter another dimension when designing objects and furniture. He believes that there should always be something magical in the object.

Describing himself as a ‘Disoñador’, a combination of the Spanish words designer and dreamer, Eugeni Quitllet likes to enter another dimension when designing objects and furniture. He believes that there should always be something magical in the object.

Eugeni Quitllet was awarded the honour of Designer of the Year for the January edition of Maison&Objet Paris 2016. Architonic met up with the Catalan designer to discuss his latest works, which were presented at a solo exhibition at the fair.

Anita Hackethal, Architonic: Can you describe the installation ‘From one-off piece to infinity’ here at Maison&Objet?

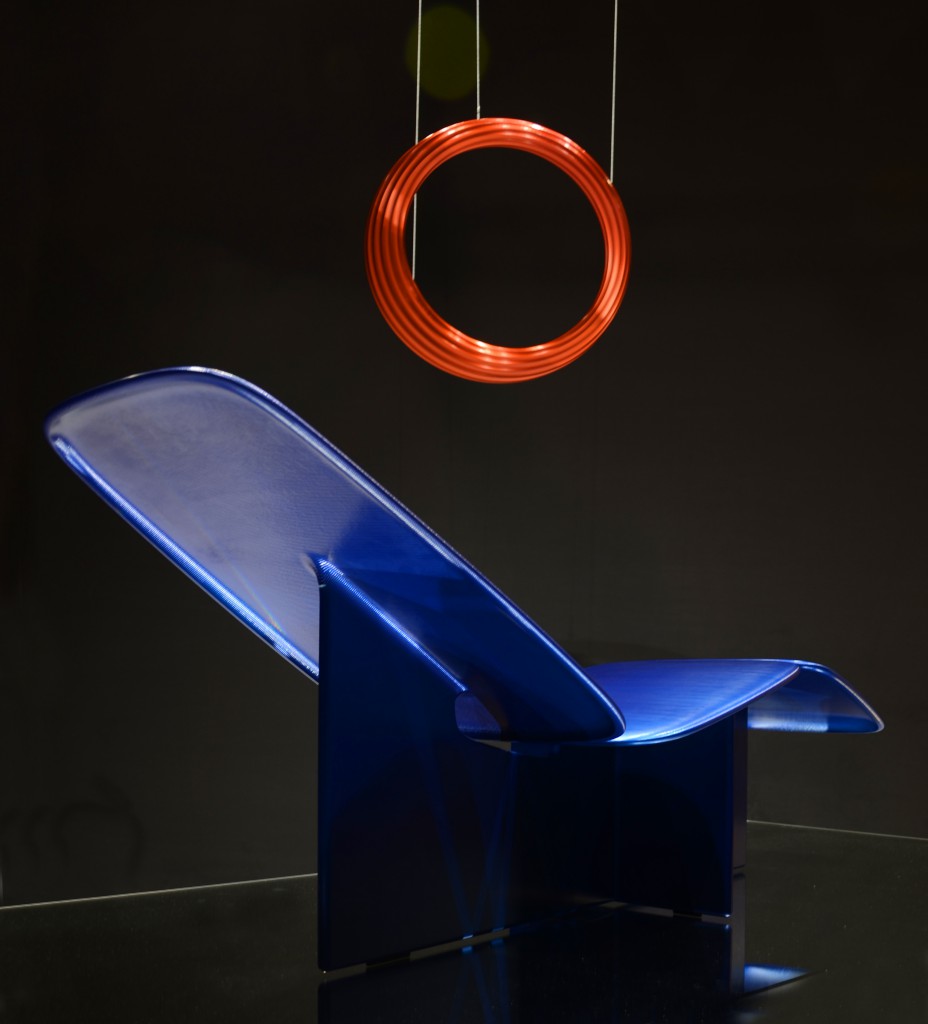

EQ: The ‘Dream catcher’ is almost like a self-portrait, because I imagine myself lying on the chair whilst looking at the spiral-shaped ring and its infinite hole of inspirations, which in a way catches my dreams. It seems as if the pieces were made in space – it is almost like being in a spaceship.

AH: Please tell us more about the process and the material that you used.

I worked together on this project with Alex Rasmussen from the family Neal Feay. The Neal Feay Studio is based in Santa Barbara and has specialised in anodised aluminium for many decades. Both of the one-off pieces are made using the CNC process, starting from a monolithic block of aluminium. With the digital design as a source, the robot is working its way through the material in very small steps and allows the beauty of the raw material to slowly appear. As for the surface, the machine creates little microwaves that remind you of ripples on water when there is vibration. I kept this structure for the skin of the chair. It’s almost like there are tiny mirrors reflecting the surrounding space. It is natural, but at the same time synthetic.

The Mobius ring is twisted, so it was quite a challenge to maintain a smooth movement on the surface, as we had to turn the piece frequently for the robot to follow the path. The aluminium pieces are then dipped into blue anodising liquid, which is what gives the material its resistance and its beautiful blue colour.

AH: Can you tell what your material preferences are when it comes to designing objects?

EQ: I like to work with all kinds of synthetic materials that are suitable for high technology and that are very connected to industrial processes. I choose materials that reflect the sensuality of shaping – plastic and aluminium, for example. When designing an object, I like to explore and push the limits of the material to the point that we don’t really understand how it was possible to make it. There are no limits with materials.

AH: You’re also showing a selection of recent works. Many of them are made of plastic.

EQ: I like plastic. It adapts to the way we are today – a fast society. Plastic is not an ecological material, but I try to push the quality to be a long-term product. Plastic will evolve naturally to something stronger and better to stay always beautiful. It can be made in a way that it is similar to crystal. I also like glass. I am just about to finish a glass project, where I am searching for magical transparency in a very industrial way. Glass has a good resistance to heat and can be used for cooking, which is more close to the human body, and more natural, as it is made of sand.

I like to domesticate technological materials and add some soul to them. Wood is already alive. Its life force comes directly from nature’s power. To plastic you have to apply this type of intelligence to bring it to a certain level. It is a perceived energy that I transmit through material.

AH: If you had to pick just one material to work with for the next three years, would it be aluminium?

EQ: I would definitely continue to work with aluminium, as I want to explore the material further. You can use it in so many ways and modify it very well. It is liquid and hard at the same time, so you can either inject it like plastic or groove it like a stone, just like Michelangelo used to do with marble. I also like the fact that you don’t lose any material. When you design a piece like this, using the CNC process, almost 75% of the raw material is taken off, but the factory collects the aluminium chips and melts them into blocks again.

This article originally appeared on Architonic, where TLMag presents articles in French and English.